success story

Interesting writing08/06/2023

Marsan group, with over 70 years of history and headquarters in Waco, is a leader in the field of surface coatings for metal parts. It currently has 6 painting facilities in 3 countries and a metal transformation plant with two divisions (one for stamping and one for electrowelding). Inycom is the technology company implementing the MES system at the Waco plant. With the integration of this system, the plant now has complete traceability of the entire production process, which can be followed from anywhere at any time.

Inycom is the technology company responsible for implementing the MES system at the Vigo plant, a key location in terms of improvements and innovations in manufacturing.

Grupo Marsan saw the need to incorporate a solution that could automatically identify all kinds of parameters, allowing full detection in real time of what was happening throughout the production process. were manually controlled.

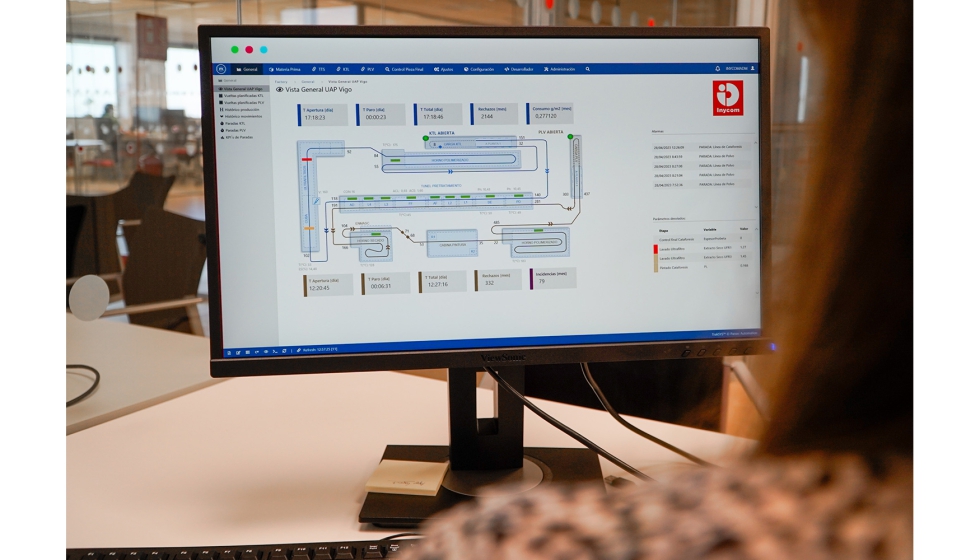

The solution proposed by Inycom Technology Company is to integrate an MES system into the plant. This software already allows Marsan to have a complete and centralized view of its entire process, at all times what is happening, where possible defects occur or, even when a product goes through a phase with deviated parameters, which is possible. Record all information as it goes down the line. All this has had a positive impact on the safety and quality of the final product offered to their customers, which is closely linked to the company’s values and the demands of its core sector, the automotive industry (IATF 16949).

Incorporating an MES into the process has helped reduce unnecessary interventions, analysis and management of information (Management by Exception, MBE), focusing only on points that require attention and handing over the remaining control to the system. That is, if the problem is not significant and within established limits, there is no need to proceed to the next step and self-monitor. It is a very valuable resource for production management and control. The available information allows for a proactive approach that allows for the establishment of preventive and predictive measures at different stages of operation, benefiting plant operators. For both strategic and operational decisions, Industry 5.0 is referred to as the fundamental pillar of human centricity, where the operator is at the center and collaborates with organizations in their day-to-day operations, improving their efficiency and productivity.

From Waco to International Mills

All developments involving Grupo Marsan start from the Vigo plant and, after a test phase at this location, are implemented at other headquarters to align processes and centralize control and knowledge. The MES system is already a corporate environment with daily use and has shown significant progress, so the aim is to expand it to other plants.

Santiago Mogo, head of Marson IT Development and the project, admitted that he was very satisfied with the first results and explained that Grupo Marson chose Inigam: he already had previous relationships with other projects. In addition, another incentive for Mogo is that Inycom integrates the main MES solution on the market, Traksys, one that offers high guarantees regarding continuous support and updates: I cannot leave Inycom because an implemented solution is needed more. We wanted a development specific to our plant and something intuitive and easy that any colleague could use. “We have achieved this quickly and we are very satisfied with the result and it is something we would recommend to any factory as it has a quick return on investment through time savings,” he agreed.

companies or related companies

Tools and Components, SA (Inycom)